C

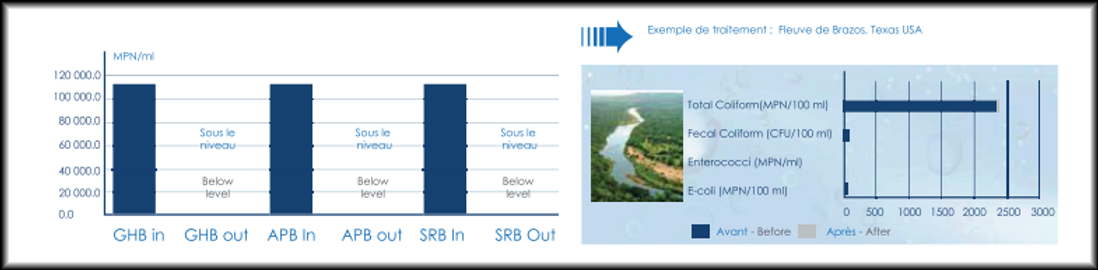

lean water uses PLANETE CLEAN WATER electro-oxidation technology which is a fixed or mobile reactor that can be quickly deployed to treat polluted fresh water. The American patented electro-oxidation process eliminates all bacteria and hydrogen sulphides (H2S). It also precipitates heavy metals, reduces solid residues to microns, which are then polished by ultrafiltration.

This technology provides serious cost savings. In fact, the operator will no longer need to deal with descaling, corrosion, solids management or hydrogen sulphides.

Additionally, this process requires NO USE OF CHEMICALS. Finally, a single machine (PCW – 1200) can process up to 50,000 barrels (7,950 M3) per day!

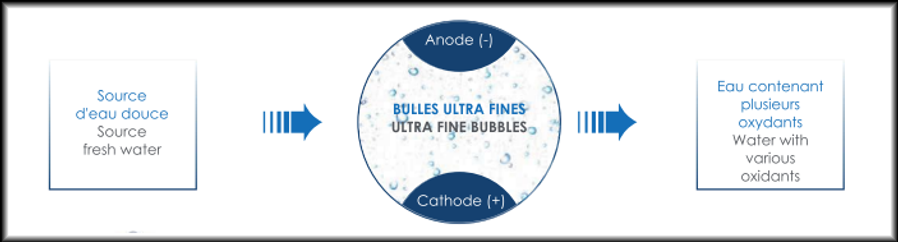

How does it work

After effective filtration, you will have water ready for use. The treated water no longer contains any bacteria; it is therefore clean, drinkable and descaled.

Direct electrolysis of water

No chemicals

No sacrificial anodes

Cost of electricity

Cost of electricity

1/3 of a hundred $/ barrel

2.1 cents $ (M3)

Enabling technologies

Electrode geometry

Exclusive coatings

Advanced controls/switching

The principle

Powerful ultrasonic cavitations and nanobubbles are incorporated in series with the reactors.

Ultrasonic cavitation creates powerful particle disruption, enhances mass transport, and induces advanced oxidation reactions through pyrolysis.

Nanobubbles enhance dissolved oxygen in water and provide oxygen for oxidation reactions.

Nano bubbles help create more oxidizing reagents in water during the electro-oxidation of various elements.

Intermittent air injection by Venturi Effect and continuous cleaning by electrode jets maintain high electrode efficiency during operations.

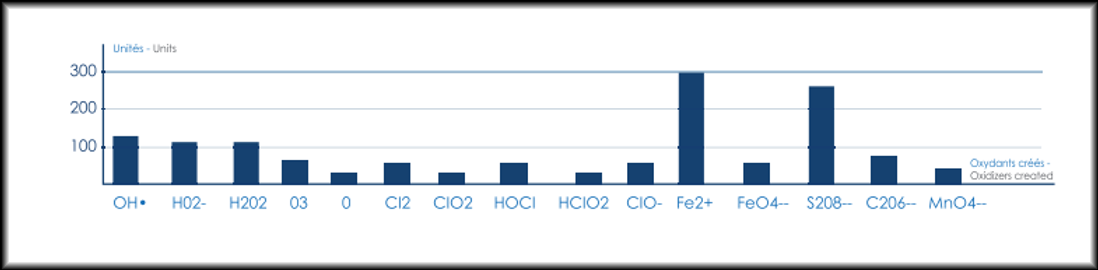

Multiple oxidants generated during the treatment process attack bacterial colonies.

Only 1 to 5 ppm remains in the treated water to ensure complete disinfection of the treated water.

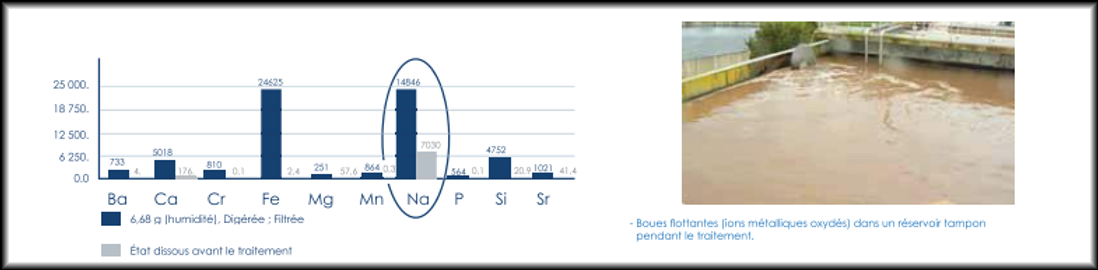

The generated oxidants and strong electric fields promote flocculation of suspended solids (TSS) while a portion of dissolved solids (TDS) is converted to TSS. Problematic metal ions are precipitated and stabilized. 6.68 g (moisture), Digested; Filtered, Dissolved state before treatment

The advantages of the system

On

Effective

Affordable

Sustainable

Mobile

Global Application

Applications

Our technology allows a large number of applications, here are a few:

INDUSTRIES

AGRICULTURE AND HYDROPONICS

OIL FIELDS

BLUE/GREEN ALGAE, NUTRIENTS

TRAFFIC JAM

MUNICIPAL WATERS

MEDICAL